In this post I’m going to show you how to build a shower niche. But not just any niche – Your own custom, floor to ceiling, 11 inch wide vertical shower niche (SN) using Wedi building panels, finished with composite marble tiles and stainless steel shelves.

Using your own preferred tile (subway tile, porcelain, ceramic) you’ll be building a super cool designer shower niche that’ll make your friends and neighbors green with envy. All you need to do is follow my super easy, step by step instructions (and video).

This how to build a shower niche post is basically a tutorial going over (in great detail) the shower niche portion of a shower remodel project I recently completed. The video below shows the build from start to finish, but I would recommend that you go through each section of this post as well, for some important additional details.

This is Steve Gehrmann from Redblock (Steve’s bio). I’m a bathroom remodeling contractor with 15 years experience, bringing you another actionable Shower Build post. To motivate you to read on, here’s what one of my commenters had to say:

“I’m starting to plan master bathroom and loved the detail of your blog”.

So let’s get into it!

How to Build a Shower Niche – Complete Video

Not your Ordinary Shampoo Niche

Topics Covered:

Step2: Framing your DIY Shower Niche

Step 3: Wedi Backerboard Installation

Step 4: How to Make a Shower Niche Waterproof

Step 5: Tile & Shelf Installation

Materials Used in this Project

Step 1: Shampoo Niches – Type and location?

The first step in my how to build a custom shower niche tutorial is deciding what type to install and where to install it.

I initially suggested to my client that a vertical SN might be better than a horizontal shower niche (she asked about both), simply because I could achieve the storage she wanted and keep it neatly tucked away within the existing stud wall without the need for the complicated extra framing and risk associated with horizontal shower niches.

My client agreed that the vertical design was the best option and decided on a floor to ceiling vertical SN because she wanted to maximize her storage, but also create a high-end architectural show piece rather than just a simple shower niche.

Then we talked about placement.

The obvious placement was within the longest wall, far enough out from the valve wall so it’s still within the footprint of the shower pan, still within easy reach, and out of the “splash zone”. The width of my framed SN opening ended up to be 13 inches, reducing to 12 inches after backerboard install, and further reducing to around 11 inches after the tile is installed. It’s finished depth, 3-1/2 inches with a height of 9 feet (just below the top wall plate).

Luckily this shower was not bordered by any exterior walls so I didn’t have to worry about applying additional waterproofing and insulation. If you’re planning to build your custom tall shower niche on an outside wall, you should read my Shower Niche Problems post.

If you’re planning on building a smaller SN (width or height), the info in this “how to build a shower niche” post (and video) will still be of great help to you since all the construction basics are pretty much the same.

If you don’t want your SN to extend vertically from floor to ceiling, you’ll need to decide on the height of your niche (off the floor) as well as the interior size. I decided on the 12″ rough width simply because of the 12 inch stainless steel shelves that my client decided to install.

Step 2: Framing your DIY Shower Niche

The second step and the first “build” step in my how to build a shower niche tutorial is installing the SN support frame. Don’t be intimidated by this step. I’ll step you through it in detail.

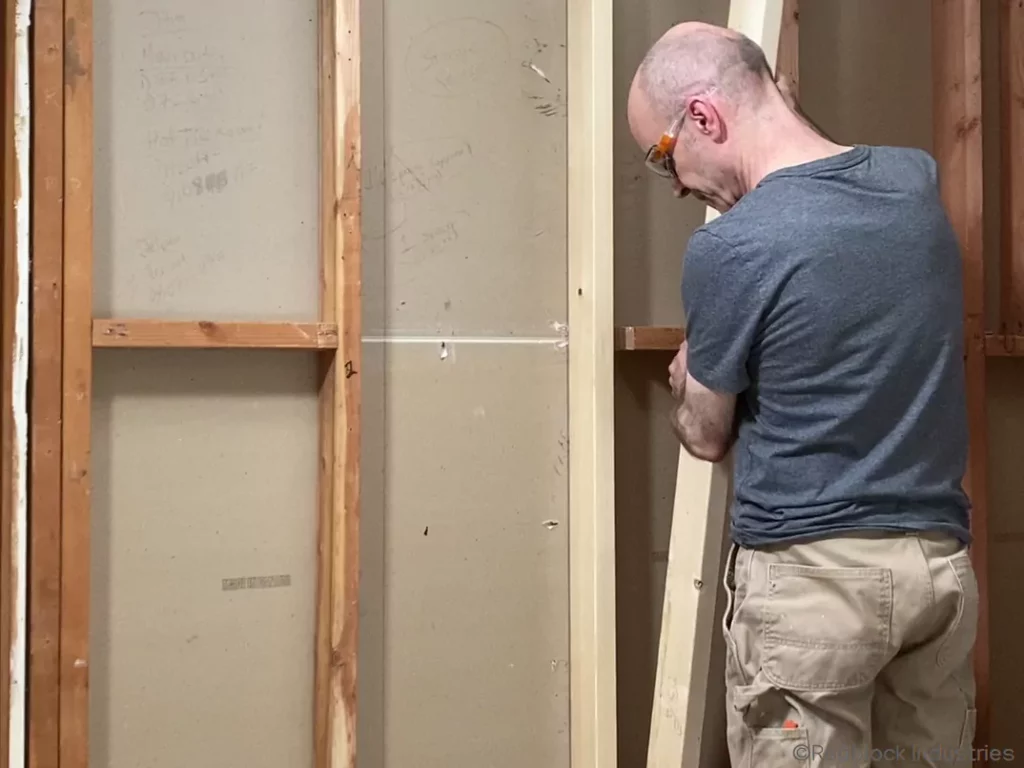

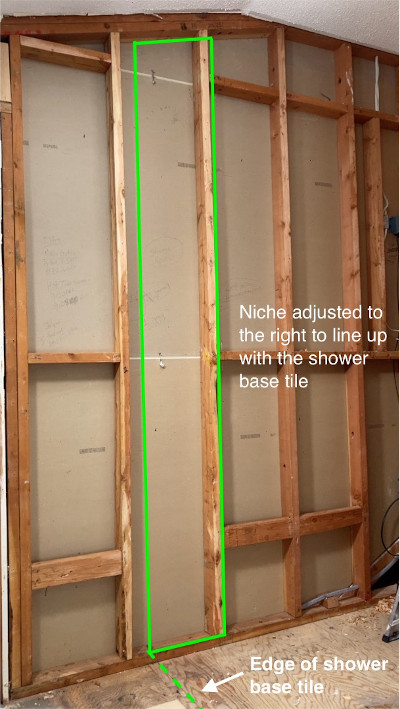

Since I wanted to line up the outer edge of SN with the edge of the shower base tile, the first thing I needed to do was to determine where the edge of the shower pan would end up.

From these measurements (and some frustrations with a wonky stud wall), I realized that I needed to move the right side stud a little to the right, to allow my new SN to line up with the edge of the shower base. I decided to remove this stud (instead of moving it to the right) because it was super warped and it was going to take too much time trying to straighten it (see image).

But before I could remove the right side stud, I needed to cut some horizontal braces in the right hand stud space.

Task 1 – Stud brace removal:

Cut the horizontal stud braces on the right side of the SN, then remove the right side stud.

And because this new SN will be floor-to-ceiling, I needed to make sure that both sides of the niche were framed with solid, double stud, structural posts.

Task 2 – Frame out the Niche:

Install studs on the left and right sides of the SN opening.

I decided to move the SN a little to the right, but even if you don’t need to do this, you’ll still have to install another support stud (or strips of plywood attached to the stud) to reduce the stud bay width to around 13 1/8 inches. This will give you the required 12 inch width after the Wedi board is installed in the SN interior (later step). Just make sure that both sides of the niche are as plumb and straight as possible.

The last part of the structural reinforcement that transforms this humble wall recess into a spectacular floor to ceiling shower niche, was to remove a section of the wall plate at the bottom of the niche. This was a bit of a delicate procedure because I had to ensure that I don’t damage the drywall on the other side of the wall, but it worked out very nicely as you can see in the video.

Another option:

Of course if you prefer to keep the bottom plate intact, that’s definitely an option. This will not achieve the floor-to-ceiling look that I was shooting for in this shower design, but you can certainly do it if you prefer that look.

And if you prefer to position the base of your SN a little higher off the floor still, you’ll obviously need to place at least one horizontal stud brace at the bottom of your SN for support. I would slope this brace 1/16 inch (from back to front) so you don’t have to mess around with sloping the backerboard or base tile. The latter is an equally good option but I prefer sloping the substrate framing or backerboard, rather than the tile as a lot of tilers do.

You’ll then have to install a piece of Wedi board on this stud brace to create the base of your SN.

Task 3 – Cut out the Plate:

Cut out a section of the bottom plate below the rough-in SN.

Step 3: Wedi Backerboard Installation

The next step in my how to build a shower niche tutorial is backer board installation. And the backer board I’m using, Wedi Foam Backer panels.

Foam Wallboard Waterproofing Membrane?

One of the best things about using Wedi Board was that it serves as both a backer board and a waterproofing membrane. This saved me the time and hassle of applying a membrane inside the SN and in the rest of the shower.

To be clear… I’m not a big fan of using foam board as both a backerboard and membrane, but this shower was surrounded by interior walls. so it was perfectly OK in this instance. If you need any more info about Shower Tile Backer Board, please visit my post on the topic.

The first board piece I decided to install was on the back wall of the SN (before attaching the panels to the shower wall).

Task 1 – Install Cement Resin Coated Wedi Foam Backer

Cut and install the Wedi board at the back of the SN.

I cut this panel so that it fits quite tightly into place with a very small bead of Wedi Joint Sealant on each side so it seals against the framing but not the drywall at the back of the SN.

The backer board pieces for the sides of the niche were cut flush with the surface of the surrounding shower wall framing and a bead of Wedi joint sealant applied to seal them against the back panel.

And they are attached to the wall studs with Wedi SS Screws and Washers.

Task 2 – Caulk the seam, Install side panels

Cut and install backer board pieces at the sides of the SN.

The last Wedi Board pieces to install were on the face of the shower wall on the left and right side of the SN. These side pieces overlapped the SN side pieces to allow the seam to face the inside of the SN. Wedi joint sealant was applied to create a watertight seal.

Task 3:

Install Wedi Board pieces on the face of the shower wall, left and right of the SN.

Task 4 – Fill in the Z notch:

Install a small piece of Wedi board to fill the base perimeter’s notch channel ( Z notch) in front of SN. This thin strip of Wedi Board actually comes with the Wedi Fundo Ligno shwr pan, which makes it easy if you’re also installing this pan (video post coming soon).

Step 4: How to Build a Shower Niche – Waterproofing

Step 4 of my how to build a shower niche tutorial is all about waterproofing the bottom of the SN.

As I mentioned previously, using Wedi Foam panels for this SN (and the shower) allowed me to skip the waterproofing membrane installation step but there are some waterproofing concerns that must be addressed when creating a floor to ceiling SN like this one.

If you’d like to find out more about shower waterproofing before continuing, you’re welcome to check out my Shower Membrane Waterproofing post.

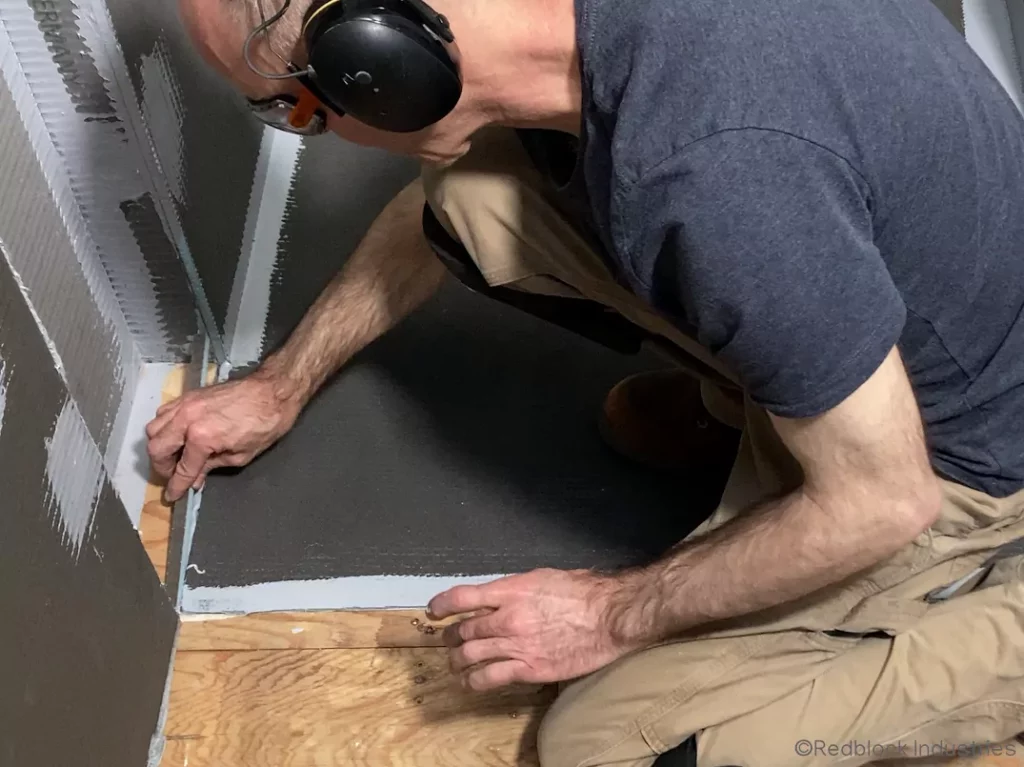

At this stage of the build, the base of the SN is still the exposed plywood subfloor (as you can see in the image). You can also see that the subfloor is recessed about 1/4″ below the shower pan. As such, it needed to be raised up to the subfloor grade before waterproofing.

I originally thought I would install a small piece of Schluter Ditra Mat to accomplish this (as I did on the floor outside the shower), but I decided to just fill it with thinset mortar instead, because it would be a bit easier to create the slope on the bottom of the SN.

Task 1 – Apply sealant and spread the mortar:

Before spreading the thinset, I applied a bonding agent (diluted Weldbond) to the plywood to seal it. Then I spread 1/4″ of thinset over the subfloor at the base of the SN. Ensure that it’s sloped outward to promote proper draining. 1/16 inch slope from back to front is all you need.

Because this SN is “curbless”, the base, and all the corners, need to be waterproofed. This is a bit of a fiddly job using a sheet membrane but I prefer this for piece of mind. Check out my waterproofing post to find out why.

In order to prevent excessive overlapping of many individual pieces of sheet membrane at the base, I decided on one carefully cut piece of Wedi Subliner Dry sheet membrane in combination with two Subliner Inside Corners, and two Subliner Outside Corners.

Task 2:

Install the cut section of Wedi Subliner Dry over shower pan seams and base of the SN.

Task 3:

Seal the joint where the SN panels meet the floor by applying two sets of Wedi Subliner Dry Inside and Outside Corners to this area.

Step 5: Tile & Shelf Installation

The next step in my how to build a shower niche tutorial is tiling and shelf installation.

If you need to find out more about shower tiling or shower shelves before you continue, you’re welcome to check out my Shower Tile Installation post and/or my 4 Go-to Shower Niche Shelf Options post.

Because this is a tiled SN, and the particular tiles chosen by my client are composite marble, I decided to expose the edges of the tiles on the sides of the SN. This involves a bit more work polishing and rounding the edges, but it looks so awesome that I needed to do it for this build.

If you’re installing ceramic or porcelain tiles, you will not have this option. Instead you’ll need to install a tile edge trim to frame the perimeter of your SN. You can see an example in this image.

Exposing the tile edges also means polishing them, which I do not have the time to cover in this post. However, I will cover the entire tile edge polishing procedure in my Tile Edge Trim post if you are interested.

Before tiling the inside of the SN, I first installed the tile on the right side of the SN.

Task 1:

Cut and set the wall tiles on the right side of the SN.

After completing the tile installation on the right side wall, I could have immediately installed the left side wall too, but I wanted to tile the SN back wall first, just to see how it looked!

Task 2:

Cut and install the tiles at the back of the niche.

First setting the shower wall tiles on both sides of the SN and making sure they create a perfect vertical line on each side of the SN opening is very important. This ensures that the sides of your SN will look perfectly plumb and straight when the side wall tiles are set in place.

Task 3:

Cut and set the wall tiles on the left side of the SN.

Once the wall tiles on each side of the niche were set in place, then it was time to cut and set the side wall tiles inside the SN.

Task 4:

Cut the side wall tiles for the niche.

Task 5:

Install the side wall tiles and the shower niche shelves into the recess.

This step of my how to build a shower niche tutorial shows how to proceed with the shelf installation.

My client decided to install the Rb3 Stainless Steel Shower Niche Shelves because she wanted plenty of storage space in her SN, but didn’t want the thick and clunky look of a tiled shelf or the slippery surface of a glass shelf. These stainless steel shelves have a very low profile and fit into a standard 1/8″ grout line space, providing the minimalist aesthetic she wanted.

Since these shelves are 1/8″ thick (slightly less), and my grout lines were around 1/16″, I needed to file the edges of these tiles a bit to make room for the shelves. I will soon be adding a section to my Shower Tile Installation post that covers this in detail so stay tuned!

Btw, if you wanted to install a glass shelf instead, you’d need to cut the side wall tiles a bit shorter to make room for the glass because they are a fair bit thicker than the stainless steel shelves I’m installing.

You can check out my Shower Shelf Options post if you’d like to see a large assortment of different shower shelves to improve your storage.

Step 6: Grouting

Step 6 in my how to build a shower niche tutorial is grouting with a good quality pre-sealed or epoxy grout.

As I’ve mentioned before, I believe that grouting with a pre-sealed or epoxy grout is important for all showers and tiled niches. As such, I decided to grout this SN and the rest of the walls with my favorite pre-sealed grout, Mapei Flexcolor CQ.

I love this product because it stays water resistant for a super long time after install and it sets rock hard (unlike some other pre-sealed grouts). The only hitch with this product (and most pre-sealed grouts) is that the application technique is a bit more involved than with regular cementitious grouts.

If you decide to use a pre-sealed grout, I would strongly suggest that you practice with it on a small area before you take on a big grouting job. If you feel some apprehension about learning a new grouting technique, you can always apply regular cementitious grout instead. But then you’ll need to seal it every year or two.

Task 1:

Grout the SN interior.

Check out my Lay Shower Tile post for more info on Flexcolor CQ and it’s application

Step 7: Tile & Grout Sealer

The last step of my how to build a shower niche tutorial is sealing the tiles.

As I mentioned above, you’ll never need to worry about sealing your grout again if you install a good pre-sealed grout in your tiling project. As such, I didn’t do any grout sealing at this stage, but I did decide to seal the tile surface with a good sealer. These tiles are made of composite marble, which is quite soft and porous, so sealing them was very important.

You can find out more about grout sealing and in my Shower Tile Installation post.

Seal the tile with a good tile sealer.

Task 2:

Apply a tiny bead of silicon around the shelves and the SN perimeter. Congratulations! You made it to the very last step in my how to build a shower niche tutorial.

Materials Used in this Project

1/2 inch Wedi Board

Wedi Screws and Washers

Wedi Joint Sealant

Wedi Subliner Dry Inside Corners and Outside Corners

Mapei Ultraflex LFT Thinset Mortar (white, modified)

Mapei Flexcolor CQ (premixed and pre-sealed)

Terazzo Renata composite marble tiles from Ann Sacks

QEP Floor and Wall Tile Leveling System

rb3 Stainless Steel Shower Niche Shelf from Redblock Industries

Wrap Up

I hope you enjoyed my how to build a shower niche tutorial.

I really enjoyed building this custom niche and writing this how to build a shower niche tutorial, because it shows how a simple niche can be transformed into an impressive architectural feature, if you’re willing to take it to the next level 🙂.

This post will be part of a series of posts (and videos) covering an entire Wedi shower build, but only the SN installation is included in this post. Stay tuned for my next posts (and video) covering the rest of this project.

Please let me know in the comments if you enjoyed my how to build a shower niche tutorial. And if you decided to take on this project, please let me know how it all turned out. You can also ask me any question you might have. I’d be happy to help you out!

Hi Brendan,

Thank you for your comment!

As I mention in my backer board post, I generally prefer using a more rigid cementitious backer board with a good waterproofing membrane.

But if I’m ever going to use a foam backer, I will always choose Wedi or Hydro Blok because their panels and pans are much more rigid due to the cement coating.

I generally use the Schluter Ditra Heat system simply because it’s easier for me to get from my local wholesaler.

I also like it a bit better because it’s easier to install than the Wedi system.

I generally don’t like to mix two systems, but the floor install and the shower install only interact at the shower pan margin, so the installations are pretty much independent of each other.

In other words, I would never use two different systems within the shower for example.

One thing I should mention about Schluter Ditra Heat – make sure you follow their instructions about how to mix the thinset mortar for installation. Most installers tend to mix it too thick so it doesn’t adhere properly to the floor.

Even if you think you’ve got the mortar consistency right, I would strongly suggest that you back butter the Ditra before laying it down.

I would also suggest that you buy the Ditra Heat kit with 3’x3′ sheets instead of the roll. This makes install so much easier.

Good Luck with your project!

Steve

I noticed that you used Wedi board for the shower backing but used Schluter for the floor of the bathroom. Any reason for using different methods for either area? I’m starting to plan master bathroom and loved the detail of your blog.

Hi Jacob,

Thank you for your comment and for the compliment!

If I understand you correctly, your water lines are running horizontally through the stud wall just above the bottom plate, and you want to create your vertical niche just above the location of the water lines.

My suggestion:

Before you attempt to “shrink the opening” between the two vertical studs, you should first install your 2×4 horizontal brace (just above the water lines) to create the base of your niche.

This would eliminate the need to “cut around the plumbing at the base to attach the 2x4s to the base plate”.

Good luck!

Steve

I just wanted to say that this looks incredible. I’m a DIYer attempting my master bath remodel and I want to add a niche. It’s a load bearing wall that also has plumbing lines running along the base plate so I don’t want to mess with reinforcing the wall to make a horizontal niche. I really like this extra large vertical niche you did. Any tips or tricks for me? If I did use those 12” shelves I will also have to shrink the opening down like you did, but I’ll still have to cut around the plumbing at the base to attach the 2x4s to the base plate.

Hi Nick,

Thank you for the compliment! I’m happy you are getting some useful info from my post.

I really like Mapei Flexcolor CQ. I use it almost exclusively now because it dries rock hard and it seems to be really good at resisting stains and mold growth as well as being easy to clean. It’s considered a “pre-sealed” grout because it contains a sealer in the mix. It comes pre-mixed so that’s also very nice. I am not certain what the longevity of this grout is but I have heard good things from clients even after 7 years of use.

This grout spreads a bit different than most regular cementitious grouts and the sponging method is different so you should practice with it a bit before doing a big job. I have a more detailed explanation about it and the technique you should use to apply it in my Shower Tile Installation post.

Good luck with your project!

Steve

Hi Steve,

Awesome tips thank you for sharing. Do you know any type of grout that does not stain and requires little to no maintenance? Ideally, we would like to use large slabs of material like swanstone but can’t find anyone to install. Shower size will be 30×30 inches. Thanks.

Nick

Hi Kim,

Thank you for your comment!

Our shower niche shelf only comes in the 12″ (300mm) length so it will not fit any of the EZ Niche or Redi Niche models, unfortunately.

If it’s too difficult to find a shelf for this niche, you could consider changing to a prefab foam niche instead (Schluter, Wedi). They are safe and reliable and regular thinset mortar bonds very well to their surface, unlike the plastic niches. I would never install a plastic niche without epoxy thinset to set the tile.

Just my two bits! 🙂

Good luck with your project!

Steve

Hi,

I am trying to find a shelf for my ez niche brand size 14×22. Do the metal niche shelves come in this size? It’s been difficult finding a smaller shelf for my niche.

Kim

Comments are closed.