Shower Backer Board - The Back Story

In the 1960’s there was no such thing as cement backerboard for shower walls. Ordinary gypsum wall board was considered to be an adequate tile backer for your shower wall and bathroom shower tile installations, simply because tile and grout was assumed to be mostly waterproof. This was the assumption at the time, and it was kind of true as long as there were no outside facing shower walls, no cracks in your tile or grout, and the issue of water vapor transmission was ignored.

As the industry started to understand the water vapor problem in the 1980’s, greenboard drywall started to be used as a tile backer in place of regular drywall, also with poor results. Wet drywall does not hold up well as a tile substrate, needless to say. It wasn't long before the industry consensus was that it is never a good idea to install drywall as tile backers.

A new tile underlayment was necessary in the shower. One with much higher performance; one that resisted liquid water leaks and water vapor, but also maintained structural integrity and a firm tile bond when exposed to moisture. Enter the Tile Backer Board (TBB).

Cement backer board for shower walls dramatically reduced the deterioration of the panel by reducing water vapor absorption and retention. This in turn reduced the expansion, contraction, and mold growth that occurred in drywall boards. These board were also made of cementitious materials so they were more rigid with high compression strength, providing a solid foundation for shower walls, as well as bathroom floors, laundry rooms, and more.

Cement backer board for shower walls meant more rigidity, and better structural integrity when attached to your shower walls, better tile bonding, and less chance of grout line cracking.

All the hard work was done, so everything was good, right?…… Well maybe not so good.

The problem was (and still is) that this “solution” didn’t address the problem of vapor transmission through the tile & grout. It also didn’t eliminate absorption and transmission through the TBB, into your shower walls.

But eventually some great waterproofing products and strategies were introduced to address the moisture/ vapor transmission problem – waterproofing membranes.

That brings us to the actual cement backer board for shower walls that are available today, and how the cement based TBB's (cementitious) differ from the other newcomers to the market, foam and glass mat TBB's. What problems do they claim to solve and which do they actually solve?

4 Types of Backers for Tile Shower Walls

There are four main types of TBB: Cement board, Fiber cement board, Glass mat tile backer board, Foam backer board (cement coated & membrane coated).

Cement Backer Board for Shower

The newer versions of the cement backer board for shower walls or Cementitious Backer Units (CBU’s), are very similar to the original cement TBB. They are all made with inorganic materials – lightly aggregated Portland cement with fiberglass reinforcement.

Cement backer board for showers are designed to be impact resistant, fire resistant as well as a rigid, efficient bonding substrate for new tile surfaces. These bullet-proof TBB's have been installed for decades for many more applications than simply shower walls. For shower pans, exterior cladding, stone and brick laying substrates, and more.

The modern versions of cement tile backer often contain polymers with a finer fiberglass mesh on front and back, as well as wrapped around the long edges for better edge performance. Most of these TBB's are moisture resistant, due to additives but cement based products absorb moisture quite readily so it is pretty much impossible to make them totally waterproof (even though one manufacturer makes this claim).

Another bonus is that the additives in most of these TBB's also allow them to resist fungal growth (mildew) and deterioration if they ever get wet. More on this later.

Cement based TBB's are generally produced in only 1/2″ thicknesses because they would be too brittle and structurally unsound if they were made any thinner.

The cost of cement board is around $10/board (3’x5′), which makes their cost about 1/3 less than the competitor’s non-cementitious TBB products. Examples include Durock Cement B by USG, Wonderboard by Custom Building Products, and PermaBase by National Gypsum

Fiber Cement Board

Fiber Cement board (FCB) is also considered a cement backer board for shower walls. There are a few versions of fiber cement backer board for showers, but they all utilize cellulose fibers (wood fibers) to make it more flexible (less brittle).

Similar to the traditional style of cement backer board for shower walls, these FCB's are also uniform in composition (not layered). Some of these TBB's incorporate a mixture of silica sand and cellulose fibers, while others use gypsum combined with cellulose fibers. They also have a uniformly dense composition, which allows them to be manufactured in 1/4″ and 1/2″ thicknesses. All FCB's also claim to resist compression, moisture and mold.

These panels can be very similar in price to the traditional style of cement backer board for showers (Durock), or as much as 1.5x the cost. Examples are Hardibacker by James Hardy and Fiberock by USG and Allura Fiber Cement Backer

Glass Mat Gypsum Board

Glass Mat Gypsum TBB is NOT a cement backer board for shower walls. It contains no cement; it's a layered product composed of a gypsum inner core with a fiberglass layer on the front and back face of the board. Although glass mat panels look much like regular gypsum wallboard, they have an entirely water resistant, paper free (mostly fiberglass) surface, and a water resistant gypsum inner core. Glass mat TBB's only come in 1/2″ thickness, because they would not be structurally rigid enough if any thinner.

These TBB's can vary in price from similar to cement board, to as much as 1.5x the cost of cement backer board. Examples of glass mat backer board: GlasRoc by Certainteed, Denshield by Georgia Pacific, and Durock Glass – Mat Tile Backerboard by USG

Foam Backer Board

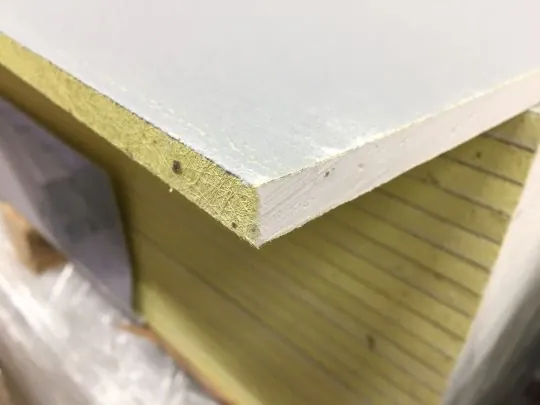

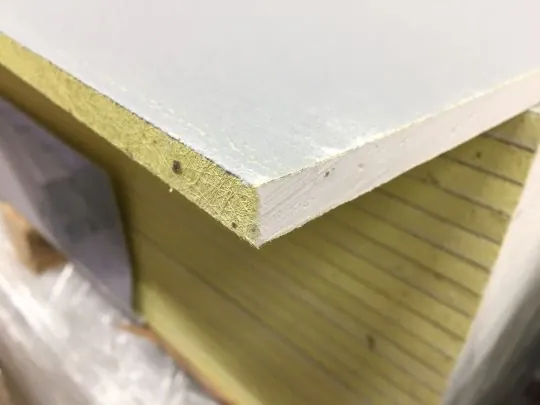

Foam TBB's are also NOT a cement backer board for shower walls. Foam TBB's are made from extruded polystyrene foam, and some are made from high density polyisocyanurate closed-cell foam. They are covered with a layer of reinforcement material (either fabric/ fleece or cement) on each side that’s also designed for bonding to thinset mortar.

These panels are up to 80% lighter than cementitious TBB's, and are highly moisture resistant. According to the manufacturer's of these TBB's, they are considered an adequate moisture barrier for most shower walls, and do not require the application of any additional liquid waterproofing membrane or sheet membrane.

Most manufacturers make them in several thicknesses so they can be used to create structural assemblies like benches, partition walls and shower niches. The minimum thickness is 1/2″ because like glass mat TBB's, they become far too flexible at thicknesses below 1/2 inch.

Foam TBB's are generally about 4x the cost of cement TBB's. The most popular of these is Kerdi Board by Schluter Systems. Another brand of this type of TBB is PermaBase Foam Tile Backer. Tile backers with a cementitious facing include GoBoard tile backer, WediBoard and KBRS Backer (KBoard), Provaboard Plus.

Backerboard for Shower Comparison Chart

NOTE: The section for “Structural Rigidity” of Glass Matt TBB contains a check, but you should keep in mind that these TBB's can be quite rigid, but only if the wall is flat. If they fracture from being distorted over an uneven wall, they can lose their structural integrity and water resistance.

TBB's - Four Primary Benefits:

Secure Mortar Bonding

The most obvious benefit of any TBB is to provide a secure bonding surface for your tile.

As I mentioned earlier, drywall was the original product used for TBB, but since drywall absorbs water vapor easily (greenboard too), big problem were associated with its use as a TBB. A wet gypsum core caused de-lamination of the paper face, which does not work out well when tiles are attached to it.

Cement backer board for showers, and all other tile backers tend to have a pre-bonded and textured surface so that thinset mortar can stick to it securely.

Structural Rigidity

Cement backer board for shower walls are still the only tile backers that guarantee high compression strength and unparalleled stiffness. This is important to limit movement and prevent your tile assembly from flexing. If your substrate flexes, cracking of the tile assembly can occur. That’s why structural rigidity is one of the most important features of any tile substrate material.

Glass mat backerboards are quite rigid, but not nearly as much as cement backer board for showers.

Their entire structure can be compromised by even the smallest water infiltration event, in wet areas like the shower. If water actually penetrates the core, it could quickly cause a cascade failure of the entire TBB. The gypsum core absorbs water very effectively, which destroys its structural integrity. This is a huge downside of this type of TBB.

Mold Resistance

Virtually every shower TBB includes this feature. It involves certain mold resistant additives and that are applied mostly to the surface of the sheet, but some manufacturers include these additives uniformly throughout the TBB.

Moisture Resistance

These days all TBB manufacturers claim that there boards are moisture resistant. This is usually a surface coating (moisture resistant TBB), or a dense surface covering (like Glass Mat BB), or a very dense, uniform consistency (like fiber cement BB). But none of these tile backers, can inhibit enough moisture to be considered a true waterproofing membrane.

The manufacturers of foam TBB's all feel quite comfortable promoting their backer panel as a “waterproof” tile underlayment because the core is made of close-celled foam, so of course they are “waterproof”. This only means that water will not flow through these panels.

A more important measure would be their ability to inhibit water vapor penetration. These foam boards can inhibit a certain amount of water vapor from moving through the board – enough for them to be considered a “waterproofing membrane”, but not a very good one. More on this below.

Because these foam TBB's can eliminate the need for an additional waterproofing membrane (in some cases), they have become quite popular with DIY installers and professionals alike.

Shower Board for Tile - Pros & Cons

Cement and Fiber Cement Board:

The best shower tile backer board in my opinion, is the fiber cement board (FCB). My go-to FCB is HardieBacker. I have to admit that FCB is the most difficult to work with, but I still prefer it because it’s the most rigid, without being brittle like cement TBB, and has one of the highest compression strengths among its competitors.

IMPORTANT NOTE: The dust produced from cutting most FCB's is very dangerous to inhale, so be sure to use a good respirator when cutting or trimming this stuff (not just a crappy particulate mask).

All the other popular TBB's have basically been engineered to make the installers job easier, whereas FCB has been engineered for performance, making it the best option out there. Cement TBB is another great option but slightly inferior to FCB because it's too brittle.

Because of the many engineering benefits of FCB, it gives me greater peace of mind. That's why I use these products for most of my shower remodel projects.

Glass Mat Backer:

I would say that glass mat is a pretty decent backer board for tile shower, but it's a confusing one because it's kind of half tile backer, and half drywall. Cutting glass mat TBB is as easy as cutting standard gypsum drywall. The problem is that the ease of cutting is the main reason that it was created, not because it’s the best material to use as a tile backer. Bottom line is, it’s OK in most situations if you install it correctly, but it does not compare to FC board.

Putting aside my bias towards FC tile backer, glass mat TBB (gypsum core) is structurally rigid enough to support basically any shower wall tile assembly on a standard stud wall. But I would like to stress that the rigidity of this type of TBB is quite minimal and may not withstand a significant impact without fracturing the grout, especially if the stud spacing is greater than 16″ on center.

And as I mentioned previously, if this TBB is not installed correctly and it results in the core is exposed to water, you will have some very big problems. Personally, I don't often install glass mat TBB on shower walls unless they are interior walls, but I do consider it a good backer board for bathroom walls, outside the shower

Foam TBB's:

The advantages of foam tile backers are that they’re very light, and water resistant. Both of these benefits are OK, but their “waterproofing” is kind of half-assed at only .36 perms for the 1/2 inch sheet. They have poor compression strength, and their foam structure makes them easy to damage and too flexible for stud spacings larger than 12-16 inches on center.

If your shower wall studs are 12-16 inches on center, AND your tiles are larger format, AND you’ve installed a sheet waterproofing membrane, AND there’s no accidental impacts against the shower wall during it’s service life, then this flex problem may not be an issue (cement coated foam TBB will reduce flexibility to a degree).

But that’s a lot of “ifs”.

The cement coated is entirely another beast. This type of foam TBB could easily be considered a cement backer board for shower walls because of its superior rigidity, compared to the standard foam TBB's.

TBB Personally, I would not install a foam backer that doesn’t have a cement facing. Also... I would not install this TBB if the stud spacing is less than 16″ on center. The biggest brand of cement faced foam tile backer is Wedi. Wedi board is the most popular cement faced foam TBB. Their pricing is a little unreasonable, but I’ve installed them many times (on interior walls) with very good results.

A Note about Mold Resistance:

This “feature” is nice… but not necessary when it comes to tile backers, in my humble opinion.

A simple fact is….. a tile and wall assembly constructed according to “best practices” would not allow any mold to grow, so “mold resistance” would be unnecessary. No significant water vapor would reach the TBB, so mold would never grow there.

However, if the wall and tile assembly were constructed incorrectly, then a mold and mildew resistant tile backer might be an advantage….. for awhile. But eventually excessive water vapor would cause any TBB to deteriorate even without mold. And if the right temperature / moisture level exists, mold will eventually grow. I’ve seen several shower demolitions where the “moldblock” shower TBB was infested with a blanket of toxic black mold after only a few years of service (see image).

Bathroom Backer Board Installation

In new construction, the TBB is often installed by the sheetrock crew, and sometimes the tile installers, who must ensure that it's firmly attached, and the integrity of the waterproofing is maintained throughout the project. To ensure that waterproofing has been applied to the seams, screw holes, and across all edges and corners.

But before the TBB is installed on the shower wall studs, you must ensure that there’s a flat surface on which to install it. That means the walls must be flat. In other words, the stud surface must be flat.

If you skip this step (most installers do), you will not have a flat surface on which to install your TBB. And if the wall surface isn’t flat, the tile mounting surface will not be flat. This can cause the TBB to warp and crack during installation, and create tile lippage, tile registration problems, when laying your tile.

Important, right? Because it’s so important and also quite involved, I will be preparing a separate post outlining how to prepare your shower walls for tile backer installation, so stay tuned!

If your shower wall studs are flat and plumb, there are a few hints below to help you correctly install your TBB.

Fiber Cement Board:

If you’re planning to install cement backer board for shower walls (including fiber cement board), you need to attach them to the wall studs correctly.

One of the biggest problems with the installation of the traditional style cement backers is that they are quite brittle and can fracture easily if the wrong screws are used. Ordinary screws (even some coated screws) can also corrode if they are not designed for moisture exposure.

I always use RockOn tile backer board screws to install any cementitious TBB panel (see image). These coated screws are corrosion resistant and can withstand the high alkalinity of a cement based TBB. Another benefit of these screws is their high/ low thread configuration. They bite into wood like nobody’s business and the thread design also makes them perfect for steel stud installation.

As I mentioned cement board is quite brittle because it’s made up of primarily cement and aggregate, but it’s also very hard. If you use the Phillips head screws, you’ll have a tough time driving these screws in deep enough to make the screw head flush with the board surface. And if you install the screws with a star-drive head you’ll definitely get it flush, but you’ll risk fracturing the board, especially at the edges and corners. The solution? Countersinking of course.

You may be thinking how in the world do I counter sink into a cement board that’s so incredibly hard? I routinely use a countersinking bit that's designed specifically for this purpose when installing any cement backer board for showers. It recesses the screw head so it doesn’t get in the way when you’re installing your waterproofing membrane and tile (see image). It also prevents fracturing the board or driving the screw in too far.

Glass Matt Backer:

Because the core of this TBB is gypsum, the screw installation method used for drywall board is pretty much the same for glass mat TBB. The difference is that you should use TBB screws instead of drywall screws.

Unlike cement backer board for shower walls, you'll need to be very careful driving screws into glass TBB because it can easily break through the TBB face, eliminating the holding force of the screw. As such, it’s best to use a stop collar when installing these screws. This bit is designed to create a depression in the face of these TBB's just deep enough to sink the screw head flush with the TBB face.

Foam Boards:

Installation of foam TBB is quite a bit different again, compared with the other tile boards.

Because these TBB's have such a flimsy low density structure, you usually need to use only the fasteners recommended by the manufacturer to attach them to the wall framing. They usually include large washers to increase the surface area of the screw head.

The big advantages of these TBB are that they function as both a tile backer, and a waterproofing membrane. So to maintain waterproof integrity, all fasteners must be covered with a sealer after installation.

This is done by troweling a sealant over the screw heads and washers or by applying a membrane “patch” that’s attached with thinset mortar.

Cement faced foam TBB panels could be considered cement backer board for show walls simply because they have a cement coating on each side and are much stronger than the regular foam backers.The most popular of these is Wedi board (see image).

Bathroom Tile Backer Board - Shower Bench and Niche

Before fiber cement backer board for shower was readily available, I was using traditional cement backer board for shower benches and niches, simply because it's tremendous rigid. But as soon as Hardiebacker fiber cement backer board for shower was available at my local wholesaler, I started using it almost exclusively for all the custom shower niches and benches I built.

The most important priority when you build a shower bench is structural rigidity. This requires very solid framing, a good cement backer board for shower applications (like Hardiebacker), and a good waterproofing membrane (preferably a sheet membrane), especially when ceramic tile is installed.

Custom shower niches do not require as much focus on structure, but still require a structurally solid TBB and adequate support framing. As such, a good cement backer board for shower applications (like Hardiebacker), is my go-to TBB for niches as well. But I've also used Wedi TBB for a few custom niches recently since it's so rigid.

Btw...I end up building a lot of custom niches for clients because of the huge (and growing) need for more storage in the shower. If I'm building a custom niche for a client, I'm often asked to create more shelf storage in their niche, or I'm asked to build a ledge on the shower wall. But as an alternative to these invasive (and expensive) storage options, I will often suggest a prefab stainless steel niche, or a fancy corner shower shelf which my clients appreciate.

FAQ's

What are the advantages of using a shower tile backer board over drywall?

Cement backer board for showers offer superior rigidity, compression strength, water resistance, and mold prevention compared to drywall or green board. It provides a solid bonding substrate for tile installation, ensuring long-lasting shower walls that can stand the abuses of the shower environment, without compromising structural integrity.

What is Tile Backer Board ?

Tile backer board (cement backer board for shower) is a structural underlayment and secure bonding surface for tile installations. Originally made of aggregated cement with fiberglass mesh, newer types can also be cementitious, but can also contain silica sand, wood fiber, gypsum, fiberglass, or foam. Other features include water resistance and mold resistance.

What thickness cement backer board for shower wall tile?

Shower tile backer board thickness should be 1/2 inch. Installing 1/4 inch tile backer on a standard stud wall causes too much deflection resulting in cracking of the tile assembly. The 1/4" thick fiber cement boards are designed mainly for flooring applications, to improve tile bonding and floor rigidity.

Wrap Up

Hopefully I’ve been successful in showing you the differences between the cementitious BB's and the foam and gypsum boards. I also hope that you've been able to figure out the best cement backer board for shower walls in your project. I’ve also tried to give you a couple of good links and suggestions for installation.

If you’d like to ask me some specific questions about this post or tips on how I could improve it, please let me know in the comment section below. I can usually answer most questions the same day they’re posted. Or if you need some more help on installation or on other bathroom remodel or shower remodel topics, please check out my shower remodel post.

Good luck with your project!

This post is for information purposes only and should not be interpreted as professional advice. You should always consult a licensed local contractor before undertaking any remodeling work in your home. Click here for my full Personal / Professional Disclosure.